Industrial Infrared Generator

|

Long Wave Infrared Generator |

|

Long IR ceramic emitters suitable for preheating and thermal treatment of plastics, latex emulsions ans synthetic fibres, heatshrinking of plastic packaging, agriculture and poultry farming, etc... High resistance to corrosive products and thermal shocks and high emitted power. Available with curved emetting surface (C) or flat emetting surface (P). Voltage : 230 V 1 phase. |

|

|

|

Connections with 2 nickel braids under ceramic beads length 100 mm. Supplied with a clip and a spring allowing their mounting on a sheet thickness 2,5 mm maxi. Elements equipped with an internal thermocouple on request. Interchangeable with english models FTE/HTE/SFE and german models FSR/FSR-2/HFS. |

|

Accessories for Long Wave Infrared Generator |

|

These sets of accessories allow the achievement of infrared heating panels using infrared ceramic generators. Particularly suitable for high ambiant temperatures, they include : - aluminium reflector (avoid the back overheat). - stainless steel terminals (for the electric connections). - high temperature ceramic clamps. - set of cross bars (for the reflector fixing). - protection grid, adaptable on every linear infrared generators (long, medium or short). |

|

|

|

Medium Wave Infrared Generator |

|

Basic models equipped with a single emitters. These appliances are robust, easy to keep in repair. They don't need cooling and can be used in hot atmosphere (up to 200°C) in every position. They allow the construction of radiating furnaces or tunnels for powder paint drying, solvent or aqueous on metallic parts. In most of the cases, they will be installed at 200 to 500 mm of the product to be heated.. Supplied with 2 adjustable attaching bolts. Accessorie : Protection grid, suitable on the reflector, it can be used with all of our linear generators long, medium and short. |

|

|

|

Short Wave Infrared Generator |

|

These appliances are equipped with a quartz short wave infrared generator mounted in front of a high reflecting parabolic reflector, covered with a thin gold coat, crimped in an aluminium profile fitted with attaching lugs. They must be installed in moderate ambiant temperature (60°C maxi). They have a thermal inertia close to zero. More, with their parabolic reflectors, they have an area of energy focusing located at about 120 mm of the emitter allowing the intensive heating of small surfaces. Voltage : 230 V 1 phase - Fixing with 2 bolts. - Connections with 2 nickel wires length 250 mm |

|

|

|

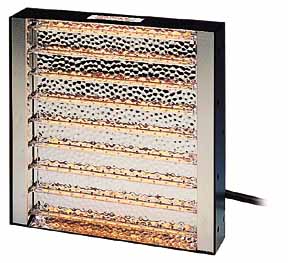

Short Wave Infrared Panels |

|

These panels consist of quartz short wave infrared emitters mountednin front of a highly reflecting metal sheet in a metallic casing with integrated cooling system. These emitters, consisting of a tungsten filament at a temperature greater than 2000°C in a quartz tube filled with halogen gas allow powers up to 180 kW/m2 while having a very low inertia (< 1 seconde). These panels are the ideal solution for the heating of moving products when over heating in case of production break is prohibited or when the overall dimensions are an essential parameter in industries such as textile, paper, plastic, food processing, coil-coating or the paint drying. |

|

|

|

Accessories : - Counter reflectors - Vitroceramic kits protection brackets. Possibility of having a panel without ventilation. Standard models : emitters for step 40 mm Emitters P/N. 6014-32 and 35, socket connection, exclusively for horizontal mounting ± 15°. Emitters P/N. 6014-34, wires connection, also for horizontal mounting. |

|

| 자세한 제품 정보는 문의해 주십시요. |

|

Copyright (c) 2007 Shin Shin International. All rights reserved.